Yesterday I fundamentally changed my perspective on sustainable design. This shift happened during the Ethical fashion 1 class I’m taking at the Fashion Institute of Technology (FIT). Our professor showed us a video of the General Manager for Nike’s Considered team, Lorrie Vogel, succinctly discuss the barriers involved in sustainable product design. Vogel emphasized that reducing our “footprint” won’t get us to the green economy; instead we have to focus on how to affordably create products that can be reclaimed and recycled (closed-loop products). What I found fascinating was when Vogel laid out the brutal reality of creating a closed-loop product:

Nike’s Three Barriers to Creating Closed-loop Products

The two largest textile materials Nike uses are polyester and cotton, both of which use scarce natural resources. Polyester uses petroleum and cotton uses way too much water and landmass. The company is trying to figure out how to reduce the environmental impact of producing these products

1. Don’t know yet how to create low-impact materials

The two largest textile materials Nike uses are polyester and cotton, both of which use scarce natural resources. Polyester uses petroleum and cotton uses way too much water and landmass.

How much water does Nike need to create one cotton t-shirt?

700 gallons (a hot tub 5 feet around and 4.5 feet deep is filled with 500 gallons)

This calculation was based on the amount of water required to grow, dye and finish one t-shirt.

How much landmass does Nike need to grow one cotton t-shirt?

1,1000 square feet of cotton

According to Vogel, 60 percent of Nike’s impact is embedded into their materials (water, wastes, toxins, and energy).

Design Question: what will be the new low-impact material?

2. It’s too expensive to manufacture recycled textiles

In 2008 Nike debuted their lightest and fastest swift suit at the Beijing Olympics. The suit was made out of recycled polyester. Yet it was 20-30% more expensive to make than using virgin polyester.

Design question: how do we cost-effectively recycle?

3. Materials cannot be clearly identified

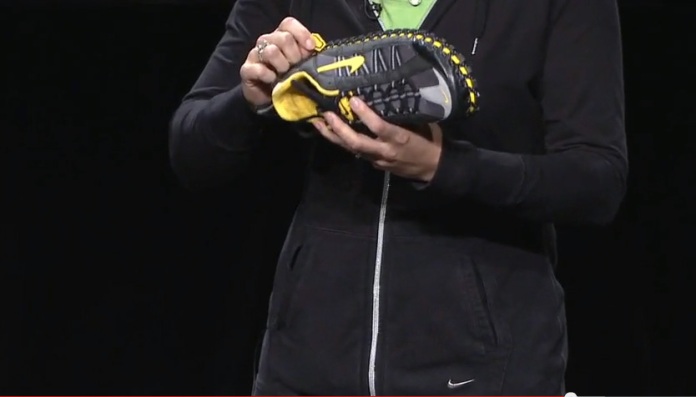

Vogel cited and example in which a Nike designer created a shoe that can be easily disassembled, to make the shoe easier to recycle.

Vogel cited and example in which a Nike designer created a shoe that can be easily disassembled, to make the shoe easier to recycle. However, when Vogel took the shoe to one of the top recyclers they told her it would be too expensive to recycle. The shoe would be grinded into a million pieces then would have to be manually sorted, mechanically sorted, water density sorted, air sorted, optically sorted, and so on.

Design question: how can we clearly identify materials to reduce the sorting process in recycling?

The good news is that these barriers don’t seem insurmountable. And we really don’t have much of a choice but to figure this out, especially when you consider what Vogel asked the audience to consider:

If it takes 700 gallons of water and 1,100 of land mass to create one cotton t-shirt, then multiply that by the number of cotton t-shirts on the planet. Think of all the materials used in all the consumer products in the world. The planet cannot sustain it, especially when you consider there will be 1/3 more people in the world by 2050.